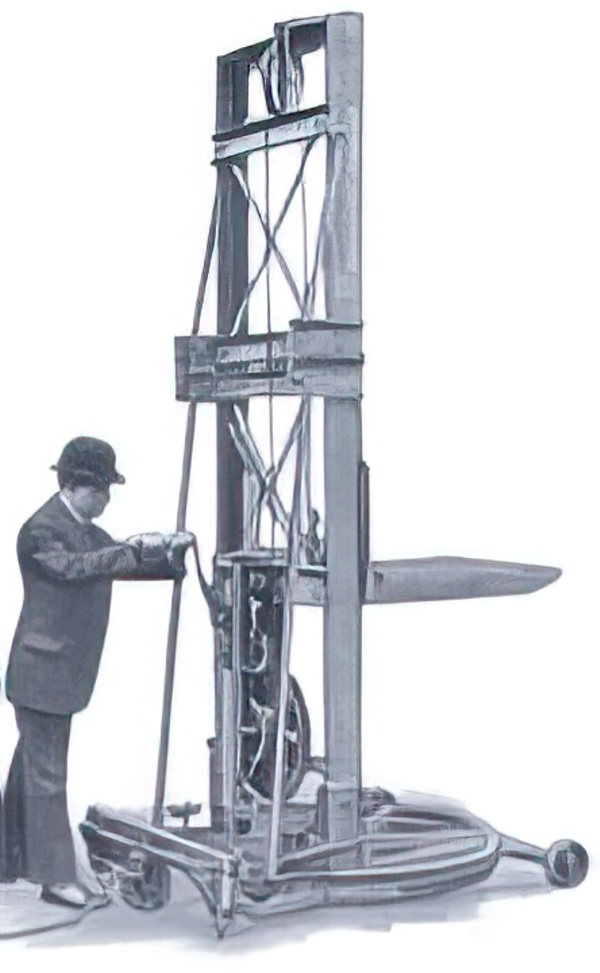

1904 – The brand name REVOLVATOR introduced the first portable elevator with a revolving base. At the forefront of the material handling industry, REVOLVATOR expanded its product line by designing and manufacturing Hydraulic Elevators, Electric Forklift Trucks, Hand Lift Trucks, Dumpers, Feed Tables, Palletizers and Coil Handling Equipment.

1956 – The first Explosion Proof truck in North America was approved by Underwriters Laboratories. These EX trucks, named REVOLVATOR, were designed in response to military defense contractor’s need to handle explosive powder and munitions. Over 20 REVOLVATOR EX units were sold to this customer and are still in service today.

1979 – The REVOLVATOR brand name was changed to GREGORY. Customers were assured of a quality forklift designed to meet their specifications with GREGORY’s continual focus on safety, performance and durability.

1996 to 1999 – A long list of product improvements and product line expansions were implemented by GREGORY. New Explosion Proof models were designed for drum dumping, drum rotating, and specialized tote operations. New features were added, such as fully programmable transistorized controls with variable speed and acceleration settings, and the electric horn and back-up alarm package. Upgrades were also made to the forklift masts and EX Scale technology.

2000 – GREGORY introduced the first powered industrial trucks tested and labeled for use in Group C hazardous environments.

2001 – The pharmaceutical operations forklift line for use in wash down and Cleanroom applications was launched. These forklifts are EX Classified and available with either 304 brushed stainless steel fabrication or painted in a white epoxy finish. Trucks are designed for tugging, tote handling, stacking, drum dumping, and special applications in pharmaceutical facilities.

2002 – The new Rider Counterbalanced Turret Explosion Proof Forklift model was announced. The RCTEX permits high density EX material handling in aisles 60″ wide.

2006 – Excalibur’s GREGORY Explosion Proof Forklift product line continued to solve EX material handling needs worldwide with 3rd party explosion proof certification for both Electric and Diesel forklifts.

2010 – Excalibur Miretti Group LLC is created as a global leader in Explosion Proof Solutions, combining Excalibur’s expertise in the Americas Explosion Proof Market and Miretti’s extensive knowledge of the European and Asian Markets. Worldwide distribution of our product line includes: Electric and Diesel Explosion Proof equipment, customized Explosion Proof solutions and conversions.

Miretti Americas joins the Miretti family of companies which includes: Miretti Srl (Italy), Miretti Deutschland GmbH (Germany), Miretti Benelux (Netherlands), Shangai Miretti Flameproof Technology Co (China), Miretti France, Miretti Singapore, Miretti UK, Miretti Hungary and Miretti Australia.

2016 – Excalibur Miretti Group expands its Excalibur truck line with its zero turn radius compact sit down series, stand-up end control rider, and its second generation rider reach unit. All featuring AC motors. We have made significant strides in our conversions of OEM forklifts as well as the scissor & boom-lift market. EMG has also introduced into the Oil and gas market its Tri-Certified engine conversions. We are now offering US, ATEX & IECEX conversions on all free standing engines.

2017 – This year features the introduction of our new corporate name, Miretti Americas. We are now better aligned to showcase our Global capabilities in meeting our customer’s EX material

handling requirements

Miretti Today

Why choose Miretti?

• Miretti Group operate all over the world.

• Miretti’s products are certifing according to ATEX, IECEx, FM, CNEx, NEC, EAC Ex standards and regulations and since April 2017 they have been in compliance with EN 1755:2015 (mandatory from novembre 2017.

• Miretti Explosion Proof Protect annually: + 1,000 mobile vehicles (diesel, electric, lpg powered trucks, hybrid, electric forklift with lithium battery); + 300 engines and customized enclosures and + 200 vehicles for mines and tunnels.

• Miretti Group invests a lot in R&D and in Training Courses (Product Education)

• Miretti Group are approved suppliers to the leading Global OEMs

• Miretti Group have been a market leaders in the explosion protection (hazardous areas) and emission control systems (reducing exhaust pollution)

• Expertise of over 45 years

• High Quality Know How in Explosion Proof & EmissionControl Systems

• Quality & Innovation

• Competitive Pricing

• Certifications & Testing

• New Technologies and Innovative Solutions

• After Sales Service always and everywhere

• Technical Department with mechanical and electrical engineers (engineering excellence)

• Training & Product Education

• Research & Development

• Reliable Customized Solutions

• Global Footprint