Explosion Proof Protection Systems for Mines and Tunnels Environments

+200

vehicles for Mining and Tunnelling sectors Ex protected annually

Accidents in tunnels can have serious consequences. When an explosion occurs in an enclosed system, the fire can spread all around rapidly and escape is difficult. Dust, gas or even both, can be present in the tunnel and potentially, they can be the responsible for an explosion.

Miretti Group, through constant research focused on new technologies and innovative solutions, can explosion protects: Multi Service Vehicles (MVS), Dumpers-Wheel Loaders, Excavators, Mixers, Personnel Carriers, Monorail, Drilling Vehicles, TBM, Ambulances, Cranes etc.

View our gallery

The Explosion Proof Protection Group I Class M2 (gas + coal’s dust) with a most temperature of 150° (450° for tunnels) guarantees the machine’s electrical and mechanical protection, motor included, in order to eliminate explosive primer’s risk.

New Ex Systems, Services and Products for Mines & Tunnels “hazardous locations”

Explosion Proof Protection Systems Mines and Tunnels Environments

All products satisfy the requirements for use in environments with presence of gas, flammable powders and coal dusts.

The target is for all contractors and OEM’s equipment manufacturers. All protection systems have to be design around every single machinery trying to keep their performances and reliability identical to the original ones. More and more frequently, OEM’s are looking for competence and experience in this very sensitive sector.

The production range also includes explosion proof sophisticated lighting systems, electricity sub-stations, data transmission and gas detection/monitoring and control systems.

Emission Control Systems for Mines & Tunnels Environments

Miretti can provide a wide range of solutions reducing exhaust pollution from machines/engine which work in mines and tunnels environments.

Miretti also adopts an environmental friendly approach by using gas purification systems for exhaust gases.

Tunnels & Mines Integrated Gas Monitoring System

Miretti can provide Integrated Safety and Security Systems (and not only simple components).

The Miretti Integrated System allows the control and monitoring of the explosive gas in combination with the pollutant substances. Our Systems can control also the tunnel ventilation apparatus.

Miretti can offer the customer a Complete Solution for the Safety and Security Management of the entire working site.

Miretti Monitoring System is supplied, integrated and certified in compliance with the main Worldwide Explosion Proof. It is also possible, on request, to have a Notified Body Approval of the entire Miretti System.

Led Explosion Proof Lights

Luminaire with high degree of protection against humidity and protective glass; passivated steel.

These news led light is suitable in any hazardous area both Group I (mining & tunnels) and Zone 1-21 and Zone 2-22 (surface).

The LED explosion proof light can be wall and pole mounted, with easy installation and wiring operations. Moreover, the soft light does not cause any glare or any eyestrain to the operating personnel.

Advantages: Total Respect of Environment | High Luminous Efficiency | Low Heat | No Radiation | Low Energy Consumption. It can work in High Vibration.

This light is very well suited for Mines and Tunnels Environments and for Paint Shops, Petrol Stations, Deposits of Solvents, Paints and Coatings and locations where a sufficient discharge / ventilation is provided.

Ex Atex Automatic Welder Machine

It is an innovative solution worldwide and an example of the excellent synergy among companies. It is an automatic wedge welder and a manual welding machine produced by Leister, converted by Miretti Group and commissioned by Mapei.

The challenge has been the development of an innovative tools, compact, light, user friendly and of course, protected following the latest ATEX Group 1 M2 rules.

Knowing in advance the needs of the technicians inside tunnes, Miretti designed a dedicated protection philosophy around the Leister welding thermoplastic polymers machine with the unique scope to offer an outstanding solution in the tunneling world wide market.

Ex Solutions: Plant Equipments & Special Projects

Miretti Ex Conversions for different types of material handling and equipment for safe use.

Miretti Ex Solutions are available for wheel loaders, tow tractors, mobile cranes, scrubbers, access platforms, dumpers, cranes, tankers, tower lights, scissor lifts, boom lifts, sweepers, tuggers, generators, wheel loaders, excavators, mixers, personnel carriers, monorails, ambulances, drilling vehicles, TBM, mining equipment etc…

Ex Tower Lights

Lighting system for Group I, composed of a tower and explosion proof metal halide floodlights.

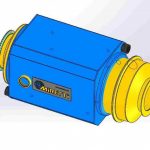

Ex Customized Enclosures

Reliable Customized Enclosures

Material: Carbon Steel or Stainless Steel

Suitable for Group I M2 – ATEX 2014/34/EU

for USA & CANADA

Marking:

Flameproof Conversion

I M2 Ex d I

Flameproof Conversion

I M2 (M2) Ex d [ia] and/or [ib] I

Flameproof Conversion

I M2 (M1) Ex d [ia] I

Class I Division 1 Group C D T3C –

Class II,III Division 1 Group E F G T3C

Ambient temperature: -20°C +55°C – Protection degree : IP 65Sizes on request.

Ex Systems for use in hazardous areas

Modular Station for Tunelling / Power & Control Cabin / Enclosed Operator Control Room

6/04 KV – 530 KVA – Ex-p Group I M2, installed on a mobile base for tunneling with presence of explosive gases.

The pressurization and cooling systems are supplied with dry compressed air by means of a standard industrial compressor. The purge allows a safe functioning in dangerous atmosphere and the air is also used to cool the apparatus.