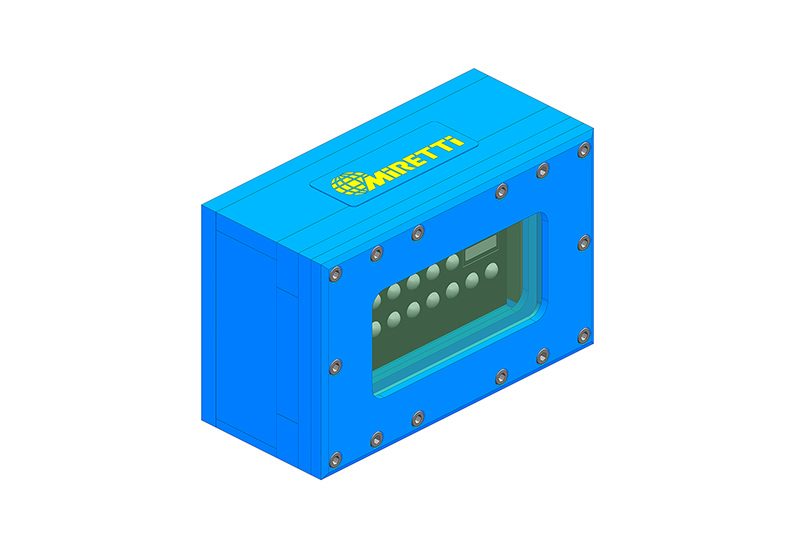

Ex Components and Ex Enclosures for use in hazardous locations

Miretti has consolidated experience in industrial flame proof/explosion proof enclosure technology.

We offer a significant range of certified explosion proof enclosures where it is possible to insert mechanical and electrical components, control units and warning lights.

Our enclosures are of various sizes and can be made of iron, stainless steel, polycarbonate, polyester.They can be used in hazardous locations.

We guarantee that our enclosures can also be customized to suit the needs of our clients.

Ex Enclosures– Reliable Customized Solutions

Miretti FilterEx

The patented Miretti FilterEX system, when combined with Miretti Zone 1 and 2 exhaust gas coolers, enables Zone 2 diesel engine equipment to operate for up to 1,000 hours before the exhaust flame trap(s) are checked and eventually cleaned.

Dedidacted to ATEX compressors, generators, pumps operating continuously without frequent interrumptions due to the maintenance of the exhaust line flame arrestor. Miretti’s technology: the bestpoke alternative to the traditional systems based on Exhaust gas cooler and Removable heavy tray that has to be replaced for cleaning every 200 working hr max.

3 benefit in 1 solutions. Compact exhaust cooling system with an embedded self-cleaning exhaust Flame and Spark arrestors: Gas cooler, Flame Arrestor, Spark Arrestor. Miretti FilterEx offer a solutions reducing cost, service manteinance, equipment downtime.

It’s an alternative approach that reduces costly service maintenance when conventional exhaust flame arrestors need to be changed every 20 hours.

Miretti CoatEx

Miretti CoatEx provides a thermal barrier between hot engine surfaces (e.g. turbochargers and exhaust manifolds) and the external atmosphere.

Enables the OEM “dry” turbocharger and manifold to be retained reducing Zone 2 conversion costs and minimising risk of failure by fitting non OEM turbo and water cooled manifold. Benefits:

Miretti DetEx System

The DetEx System is an “active” protection that we can apply for the Category 3 ex-proof conversion of any type of diesel or electric equipment. It combines gas detection with various explosion protection methods.

This system keeps the operator constantly informed about the presence in the operating area of dangerous explosive gasses or vapours. The system provides an audible and visual warning when it detects the presence of a gas or vapour at 10% Lower Explosive Limit (LEL) propane in air. When at 25% LEL, the protected equipment automatically shuts down, thus eliminating any kind of explosion risk.

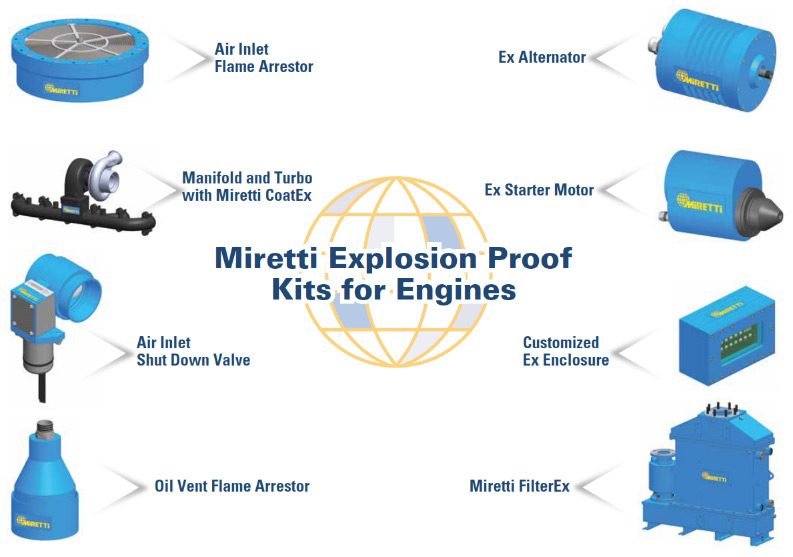

Miretti Explosion Proof Engine Kits

Miretti Group has developed a range of Engine Explosion Protection Kits:

1.for Marine wet turbo and exhaust manifold

2.for Industrial dry turbo and dry manifol

In compliace with ATEX Zone 2, Group I M2 (mines and tunnels), Class I Div.1-2 (USA market)

Zone 2 ATEX compliant kits, reliable and safe, optimized for installation and ‘uptime’, maintenance friendly with FilterEx self-cleaning exhaust flame traps and spark arrestor elimination.

Spark Arrestor

Miretti Spark Arrestor is designed to stop the sparks could be exit outside the exhaust system of diesel forklift, earth movie machines and others diesel vehicles like dump trucks, telehandlers, cranes, tower lights, tow tractors.

These parts are certified for Group I and II (Category 2G/2D/3G/3D) but can be installed also for not Atex applications or other classified zones. Miretti Spark Arrestors can be made in Basic or Personalized version, in Aisi 304 or Aisi 316L, and also in Silenced type.

– Working Light

– Tun Signal Light

– Flashing Lights

– IP67 Working Light

– Multifunctional Tail Lights

– Led Explosion Proof Lights

– Etc…